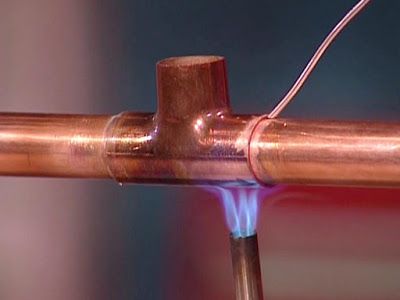

Brazing

Brazing is a metal-bonding process in which two or more metals are joined together by melting and flowing a filler metal into the joint. The filler metal shall have a lower melting point than the metal to be adjoined. Brazing is different from welding because it does not involve melting the work pieces. Brazing also differs from soldering since it uses a higher temperature and more compact fitted parts than when soldering. During the brazing process, the filler metal flows into the minute gap between close-fitting parts through the principle of capillary action.

Types

- Torch or manual brazing

- Induction brazing

- Resistance brazing

- Vacuum brazing

Brazing Components

- silver

- copper

- manganese

- nickel

- chromium

Applications

- The bonding of a variety of metals, dissimilar metals and even some non-metals is possible with brazing.

- In brazing tolerances of the component are more accurately maintained than compared to welding, as it does not melt the base metal.

- Brazing joints are corrosion resistant.

- Thin sheets and pipes which cannot be welded, can be joined by brazing.

- Brazing provides excellent sealing compared to other processes.

- Brazing processes can be easy to automate for bulk production.